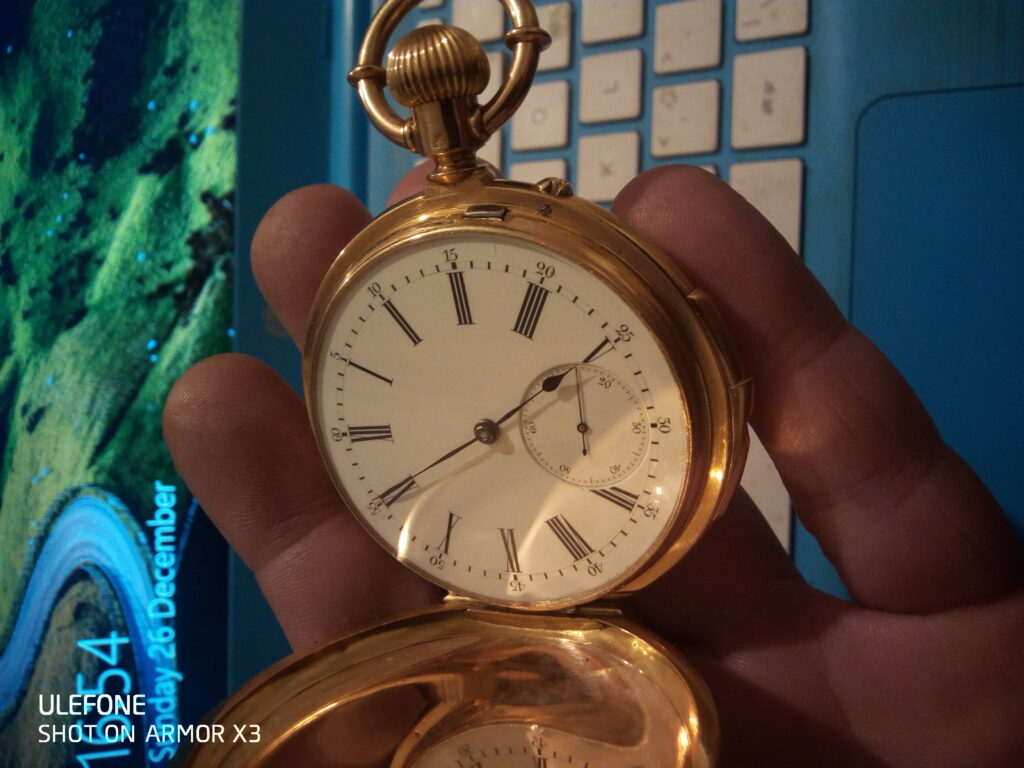

The subject line says it all really, in that we had an expensive pocket watch in with broken glass. The glass was particularly thin and nothing “off the shelf” was ever going to fit. So we made our own.

We did this by cutting the glass blank with a ceramic lathe to exact diameter and then, having made a jigg, used a glass furnace to recreate the original convex curve. The end job is indistinguishable from the original although it is stronger, perfectly polished and a peffect fit.

The cost for this, including a very thorough service was under £1000 on a chiming gold pocket watch valued at around £7000. We are brilliant value for money and have equipment which others simply dont have. I genuinely believe that this job would have had to go to Switzerland for serveral times the cost and I doubt the job we made of it was not just incredibly cheap but also the best possible results in terms of quality finish, materials and strength.

I dont usually do bragging articles but the reason I am doing so on this occassion is that if you a have smashed special fit glass we can do it and we are one of very few organisations that do.

Brilliant job of which we are very proud.

Recent Comments