I am not available for the clock clinic I’m Saturday until the 23rd of August. I will not answer the phone and there is little point in emailing me. The email service is essentially cancelled as I get too many people people asking for hints and tips for free. It pains me to say this but profit is impossible if 50% of phone calls are “I’ve taken the clock apart and there are some spare bits, and what should I do?”. I actually enjoy these calls but I have paying work to complete. Sounds awful but it’s just commercial reality if I am to maintain a cost my main business value of helping people at an affordable price.

Author: clockadmin

Massive email backlog.

Because I am literally the only free resource of project specific advice online I am unable to use email anymore. As an example 40% of my time is now unpaid advice via email.

I still enjoy helping people with basic questions and quotes but doing this via email is not economically viable.

From hereon I will only be available on the phone (07462 269 529).

This is not a decision I have taken lightly – it’s just common sense. Why are we emailing each other all the time when a phone call is far more pleasant, efficient and gives you the estimate / conversation you would have wanted in the first place.

ill be removing my email address from the website shortly and expect a %20 increase in customer service.

All the very best,

Justin

For the heroes of clockery who are at their wits end.

I get enough email from amatieur clockists asking for advice. Every clock is different and thats the challenge. I can only offer general advice and that annoys me. Its your fight and you have to persist. If you dont you fail (which is allowed) Its about something else. Its a passion and drive to defeat the gods by knowing their game. It comes with time and hard work. It takes dedication.

Email from Phil Harris – Black Country Living Museum

Ok so this is not actually a blog by Phil but he sent me an email asking why I had not published much recently and if I was OK. Firstly, how bloody nice!. You know if we were all the men that Phil is the world would be a much happier place. Luckily we do have people like Phil and you (hey, why would you be reading this otherwise – its not exactly a summer blockbuster). Incidentally, the reason I dont post as much as I used to is that I now have more responsibities as the business grows. I still love blogging and I will try to make more time for it. At the moment, every second I spend on the keyboard as opposed to the tools ends up costing people who rely on my money or time.

Anyway, back to the point of this post,

You know, people think Curators are some sort of security force or official at a Museum. This article will change your mind about that. Bear in mind that Phil looks after a limited classification of items. I dont think hes into everything, for instance weaving technologies / spinning jenny although to be absolutely honest I dont know and he may be the words foremost expert on 19th century weaving machinery – It really would not surprise me.

The reason Im publishing this is as a doff of the old cap to those brilliant individuals who keep our industrial, engineering heritage alive with their own efforts (as a vollunteer as you will find most curators are). This is important because there is no difference between Elon Musk and the early road builders like Macaddam. You have heard of Macaddam and you think probably think its a brand to do with tarmac (which probably is a brand), but Maccadam was not a brand (I dont think – dont sue me!). He invented a process for laying roads using smaller stones than paving stones. This homogenation of the particulates in road surfaces (all the same sized smallish stones) uncovered what is essentailly a fluid dynamics principle that locks particles within a varying tollerance into what is best considered as an alloy matrix. If you put a load of grapefruit sized stones with a load of walnut sized stones and then lay that down as a foundation of a road, it will cause rutting. You can even see this on modern roads where there are two distinct tracks on the road infront that follow the tracking of everyones wheels.

Macaddam must have spent some time working with different stone sized mixtures to work out the best mix to avoid ruttting. You know that because his tennet was, I believe, “if you can fit the stone in your mouth, its too big for the road”.

That implies measurement and testing. It also means this bloke understood fluid dynamics, even if those principles had not been named centuries later. I mean you have to love it. We were still in the stone age until the mid 18th Century….. or were we?. DId the architechts of Stone Henge lay thier surrounding roads and discover the same thing via repeatable experimentation (the scientific method – formalised by Galileo Galilee in 1650 or so). Who knows. There is always more to do in archaeology

Its all facinating and very intyeresting to find out what you could be if you just do something like work out how to make a better road, even if you dont really understand how its better.

This is the sort of information curators have. People who go to Museums and dont ask curators (available) for information are wasting a huge opportunity. Its lilke buying a blook and then ripping out all the pages that dont have a picture on them.

Anyway, here is Phils emial (very lightly edited for publication but all his own words). There are a some gems in this email……..

Hi Justin, I hope you are keeping well.

I haven’t been in touch for a while, basically because I was a bit worried about you as you hadn’t been posting on your brilliant blog since last March. However today I found your most recent blogs plus your latest piece on Vienna Regulators, and it has prompted me to write to you because I have just been given one! A rather nice Concordia twin-weight Vienna Regulator from about 1883 in a large handsome walnut case. It had been dropped and the pendulum rod was broken. I haven’t stripped it down yet, so I found your latest blog post very helpful. Although I’ve restored several “Vienna-style” spring-driven clocks before, I’ve never had a proper weight-driven regulator and your advice is very sound. To me, it looks in engineering terms a bit like an over-sized and fast-running 400-day clock; the pivots are tiny, the weights aren’t heavy at all, and the pendulum is massive. Apparently the Concordia factory was set up in Germany by ex-Gustav Becker employees, and although the movement is unsigned it is almost identical to a GB. I will take a great deal of care whilst restoring it. Picture attached.

While I’m writing, I hope you don’t mind my sharing the two latest clocks I’ve overhauled for the Black Country Living Museum. The first was an old (1860-ish) Anglo-American clock that they found in semi-derelict and filthy condition under a bed in a disused room. To cut a long story short, this clock was so worn-out it should really have been scrapped, and it took me months to get it going. Someone previously had stripped out the entire strike train, which is why you’ll notice there’s only one winding hole… Almost every pivot hole needed bushing; every trundle in every lantern pinion needed replacing; every wheel tooth needed filing back to a sensible profile; the mainspring needed replacing; the click and rivet were replaced; the dial needed replacing and so did the pendulum bob. Having done all that and more, and cleaned up and French polished the case, it looks good in its new home, the public bar of the recently-opened Elephant & Castle pub. Photos attached.

The second one was a 12″ English Dial fusee timepiece with a short pendulum. The pendulum was missing completely, and it took me some time to source a replacement and get it running to time, but again it looks just the job in the pub’s Smoke Room. I’d never tackled a fusee movement before. This one had no maker’s name on it, but it was a good quality movement, the fusee cable was perfect and the mainspring was smooth, so I chickened out of removing the spring as I didn’t trust my spring winder to hold the power. The other repair demands a confession, which I’ll happily admit to you. The escape wheel had one tooth about half the length of the others. The clock runs for a whole week and keeps perfect time throughout, so I’m happy and so are the Museum! Photo attached.

With my very best wishes,

Phil

[Justin – These are NOT easy clocks – specially the Regulator / Tall Clock. Maximum respect. Even the fusee is a right….]

Ive been busy. Apogies to those who follow this blog. Vienna regulators.

Ok so Ive been rather busy for ages and Ive not pubished to this blog for some time. I enjoy writing it and I know it helps people who want to get into clock mechanics. Education within my community has always been a fundemental from the beginning and I have neglected you. I apologise.

So I feel obliged to pubilish something useful to somebody. That somebody is the person who owns what is known as a regulator, Vienna or otherwise.

These clocks are the devil incarnate. They operate on a very low power consumption and will refuse to work if you speak to them innapropriately (we all talk to our clocks….dont we?. Ok forget I said that).

The longcase clock was developed for accuracy. To cut a long story short the pendulum as a regulatory device spawned the long case clock, however, the prinicple of a long pendulum delivering increasing levels of accuracy comesurate with its length, then began to exetend to other types of clock. Furthermore, with the increase in engineering precision it was possible to not only have a long pendulum providing accurate beat consistency, but it did not really matter what type of clock had that long pendulum. It could be a wall clock for instance. Or a tower clock with the vertical space available.

Because clocks were the top tech of their time, at least that available to the public buyer, there was an almost unstopable market force towards convenience, price and refinement. That is where Vienna regulators come from. Those simple design propositions driven by knowledge and experience. With the development of the regulator you no longer had to have the granfather clock which was essentially a large wooden butler standing in your hallway hicupping every second. You could have a wall mounted piece of techno beauty on your study wall, quietly advising you of the EXACT time.

What a lot of Vienna Regulator owners these days dont appreaciate is why these clock were practical, accurate, and advanced. They were the Tesla Phone of their time. Ill qualify that. A Tesla phone works from a sattelite. Not through wires in the ground. This means it is a step change in the engineering of communication. It doesnt suffer from terrestrial problems of physical “connection” or the frailty of borders or law. It sends your words to the sky and returns them to your desired destination without the majority of connection predjudice (wars, power outages, idiots, profit) and is worthy becuase it is indescrimate. It provides the same simple connection architechture that seems to define successful modern communications.

In the same way the regulator took the basic priniciples of the pendulums newtonian regularity in oscillation to the wall, not the floor. You have to remember that at the time these were produced the only reliable accurate time could be obtained by clumsy floor standing devices or a church. Or a very expensive pocket watch.

To take this accuracy out of the chapel or hallway some adjustments to the ratio of things were required. Firstly, you cant hang 25kg of weights onto the wall withou the whole clock ripping itself from its fixings and becoming modern art on the floor. To achieve the same, or better accuracy, from a wall clock would mean a long pendulum interfaced to a movement that required far less power (think KG) to work. So the regulator was born.

These devices are accurate. They are also particularly low power consumption per tick and tock. Compare the shaving foam cannister sized weights on a regulator with the massive 12kg plus weights on a long case clock. There is a massive degree of difference. So to make what is effectively a wall mounted grandfather clock, something had to be changed. This was the refinement of the mechanics to provide a low friction and energy consumption device.

As a clock repairer this presents problems. With a Gradfather clock you have a huge amount of grunt available to drive the gearing. This means that the cogs dont have to mesh exactly, the friction generated within the mechanism is almost incidental and of no great importance because there is so much power. With a regulator this is turned on its head. The machines are designed to almost conserve power. They operate as accurately as a long case clock but at 20% of the power on roughly the same dial size (all things considered).

Fundementally Vienna regulators use loads of refinement and vectors and spectors/indian shamam spirits and angles to achieve the same thing as a long case. The cost is complexity and low wear tollerances.

I probably get one call a week from someone asking me (as a last resort because they have attempted a home fix),”why does it only run for 3 hours, all it did was change the cables”. The answer is that the clock is so accurately balanced between perpetual motion with a tiny power input, and a clock that consumes more potentail and kinetic energy than the drive (weights) provide.

You may well have taken your regulator apart. You found a relatively low quantity of gears and simplistic engineering design overall. You probably didnt notice just how thin or small the connecting components connection points are. You wont have noticed that the pallets are two bits of carbon steel with screw down variable settings so that you can adjust very precisely how much pallet connects with how much escape wheel tooth. You probably thought it was just another variant of standard clock gearing and functional modules (power, gearing, regulation).

It is hard to overstate the importance of these physical ratios in a regulator. It really is beyond mathematics. With a regulator everything is pushed to the edge of its performance within the power available from two relatively small weights that run the clock for EIGHT sodding days.

Repairing these clocks or servicing them is an absolute nightmare. Its near impossible to quote for these jobs because, potentailly, it could involve re-refining all the gear train components as well as setting the pallets to the right level above the escapement to within thousands of an inch. All of which has to be done by test. There are no manuals. There is no other knowledge on the engineering settings of your clock other than that contained in your service partners brain.

So, if you want your 4ft regulator fixed there are a few things worth considering.

Fistly, if youve already tried yourself because your reckon you know what you are doing and you worked in engineering, but are now retired, you probably quadrupled your repair bill. Your service partner will have no indication of “what was” because youve changed settings, and effecively erased the original settings, by buggering around with it. This means the repair will be based on a first pass of replacing wear, and a much longer phase of working out how all the forces in the gearing deliver a result.

Secondly, do not let anyone touch your precious clock who does not have considerable experience in working with these machines. When I started I lost a shed load of money spending rediculous hours working out what worked and where the likely weaknesses in an machine were. What will probably happen if you give one of these clock to anyone that is less than “advanced”, is that you will not seee your clock for at least a year at which point you will eventually have the “errr.. we cant do it” discussion.

I love all clocks but there is special place in my heart for these time keepers. It is a black bit. Yes you read it right, I dont like these machines simply because its just so easy to underplay the potentail costs and problems.

Thats the negative view of a stressed out clock repairer. My view is that they are beautiful fantastic machines that will keep better time than your Rolex. I know that for a fact. BUT you have to respect the design and principles of these incredible machines before owning one or you will not budget for maintenance at the correct level and end up with a clock you can not bear to lose but cannot afford to fix. Like a hanging corpse.

I may need to go back and redo that “making your business attractive to potential clients” course.

1930’s Long case – Deco. Pendulum Adjustment.

This is a quick one to thank my peers in the craft. Its how to adjust the pendum settings on a domed top, arabic with brass bezel, long case clock. If you are reading this you already know what Im talking about. That said this is for my more advanced readers as well so Ill publish with that in mind.

The pendulum leader has a turning wheel on it. This is there to allow for horizontal alignment of the beat/balance settting process. This hower has a larger guage balance setter in the form of a pallet arbour clutch.

If you get a situation where the wheel doesnt achieve the desired horzontal offset you can remove the pendulum and while holding the suspension spring, force the whole leader left of right beyond its point of natural resistance. I had one of these as a job, and I did this without removing the face or taking the whole shelf and movement out. This is why Im pulishing it; it took half the time and money discovering this “blind”, so I know it can be done by others.

Also these clocks are absolute nightmares to repair generally. The chime control system is under-specified, for the size and of forces the the massive wheights they have can take. Basically, in my opinion the things are a large mantle clock movements in a long cases…….

With massive torque and revolutions per operation. The top level flys clutch sytem fails, then top pinions on it spiin too fast and its rattling or so badly bush worn it take the whole gear train torque transfer down by about 50%. If this was a car (an analogy I ofter use), it would be an Alfa Romeo. Absolutely beautiful, exquisite lightly specified components, and a lot of power in comparison to other long case, and generally much older, clocks. Im not sure if the people who get to own these clocks, often inherited, understand that have been handed a financial bomb with a lit fuse.

Still, intersting clocks when they are completely mechanically restored as they normally have epic chimes.

What cuckoo clock is right for you?

People often approach me to buy cuckoo clocks and are quite surprised when I say I dont sell them, only repair them.

Thats not really a choice for me because despite my efforts to slow the earth and create a 30 hour day (where is Superman when you need him) I really dont have time to sell and fix. Selling clocks is….mostly administration. Its boring. I have no idea what the profit margins are and if I were to sell a cuckoo clock Im the sort of person who would start a cuckoo clock building company. I know exactly the sort of clocks I would make and they would be put together in a way that addresses the problems Ive seen with cuckoo clocks over the years. And heres the thing. Ive just realised I probably know more about cuckoo clock repairs than anyone else in the UK. You might think that the people who sold the clocks you can buy would be the same people that you would go to in order to service the clock every few years but people who sell cuckoo clocks generally dont have a clue on how to service them. Its a peculiar sector or the market because most clocks are bought on holiday and cant be taken back to the original source of purchase independent reapairers like myself take on this role.

Loestcher actually rung me and asked me to become their UK service Centre after seeming some of my blog posts about Antique cuckoo clock restorations. The older clocks are more complicated and we do those. Wooden cage movement clocks dating back to the mid Victorian period often make up a lot of what we do in any given month. I think the best one we have done so far is here…

Anyway this article isnt about bragging or emphasising a specialism, its about what I would think about if I was asked to recomment a cuckoo clock bought new from retail / online

Ive seen, I think, evey type of cuckoo clock made since 1850. Through that I have learned the evolution of this strange branch of Horology. Cuckoo clocks were the first clocks made more for looks than time keeping. You dont need a bird popping out every hour or half hour advising you of the time. You have a watch or a phone.

So cuckoo clocks are about fun. Its really is as simple as that. They are delightful for grandchildren to visit . Interestingly the two most connected things between cuckoo clocks (and their repair) is children, due to the fact that they get exited about the cuckoo coming out and will actually wait, on the hour, to see the bird come out and cuckoo. If the cuckoo doesn’t come out exactly on the hour a lot of children get impatient and try and encourage it by pulling the weigths shaped like pine cones (not exactly discouraging).

Because the clocks are mounted quite high on the wall to allow the chain to drop through 24 hours use, the children pull the chains.. This results in the clock either being wound up so that it jams because the chains are pulled to hard (stretches or breaks the chains), or the clock coming off the wall and smashing to bits (and I get sent a puzzle of bits). About 1 in 8 clocks are sent to us after a child has played “Tarzan” on the chains. What amazed me at first was that no child got injured but then it dawned on me that so see the cuckoo, if your only 2 to 4 feet high, means standing back so you can see the cuckoo door. It also means you are not directly in the path of the falling clock. Its got to the point where if a customer tells me the “clock just fell off the wall” I will ask if the grandchildren have visited recently.

Sorry I am going off at a tangent. I will now tell you about cuckoo clock types and why you should buy each dependent on budget and circumstance.

By far, the best cuckoo clock you can buy is a two weight (275g per weight) small cuckoo clock for up to £500. If you buy a 3 weight clock then it means its got a music box. If you put a music box in a craft clock built by a few people in a Bavarian shed then you can be pretty sure they have either guessed at the power requirement to drive two machines (the movement and the music box). You cant do the torque calculations that will lead you to the theoretical power required to keep the clock going and the music box every half hour. The gearing is not precise enough and the mechanics that lift a bar allowing the cuckoo to go off and then start the movement are pointless to calculate. There is too much variance in the hand building process. So what happens is that somebody designs a clock around standard components and their own styling and they build it. On day one it works find but then if they have cut costs by specifying a music box with a platic worm gear (for instance), while it all works on paper, after a few years it doesnt work. Repairing clocks with music boxes is twice the price of repairing one without.

If you want something a bit more exotic then there is a huge choice of various machines and makers. In terms of clock hierarchy there are three main brands. Loetscher, Huber Herr, and Schnieder. There are others of course but in terms of industry prescience I would say these are the top three. These companies produce some truely impressive machines with dancers, wood cutters, water wheels and moving animals. The only problem is that each of these features are driven bu the weights and Ive noticed some clock manufacturers balance the quantity of power to drive them, plus the power to keep the clock going, quite closely. This means that any reduction in efficientcy via fouling or dust build up stops the clock much more easily than the same amount of fouling on a much more cheaper and equally as fun cheaper two weight.

Servicing every seven to ten years on one of these big 3 weights is…heavy. £400 or so and many larger and more complex clocks have components that are out of production in a few years if he model doesnt sell well. This means paying more, much more, for a fix. Also as you can imagine, all this extra functionality comes at the additional cost – wear. Movement manufacturers, as a general rule, do not produce a movement specific to a power rating (the weight of your pine cone weights), so an arbor and plate thickness is designed to hold “an average” weight”.

Anything running more than 1kg weights will simply wear out more quickly. If the manufacturer cant provide spares then you have to effectively “re-purchase” half the mechanics once the clock is worn, generally after far less time than that of a 275g 2 weight cuckoo only based machine.

Up to 420g will give an average lifetime of 20 to 30 years whereas an unserviced big 1500g 3 weight clock is a third of that. My clock is about 140 years old, double fusee driven 8 day machine and I can tell you for a fact that if I did not love it more than anything else I own apart from my vintage watch (oh and my kids), I would not entertain it. Its too expensive to wear down. I dont run it – I just gloat over it.

The size of your clock is all about the size of our clock. Bigger clock, bigger cost. Such is life.

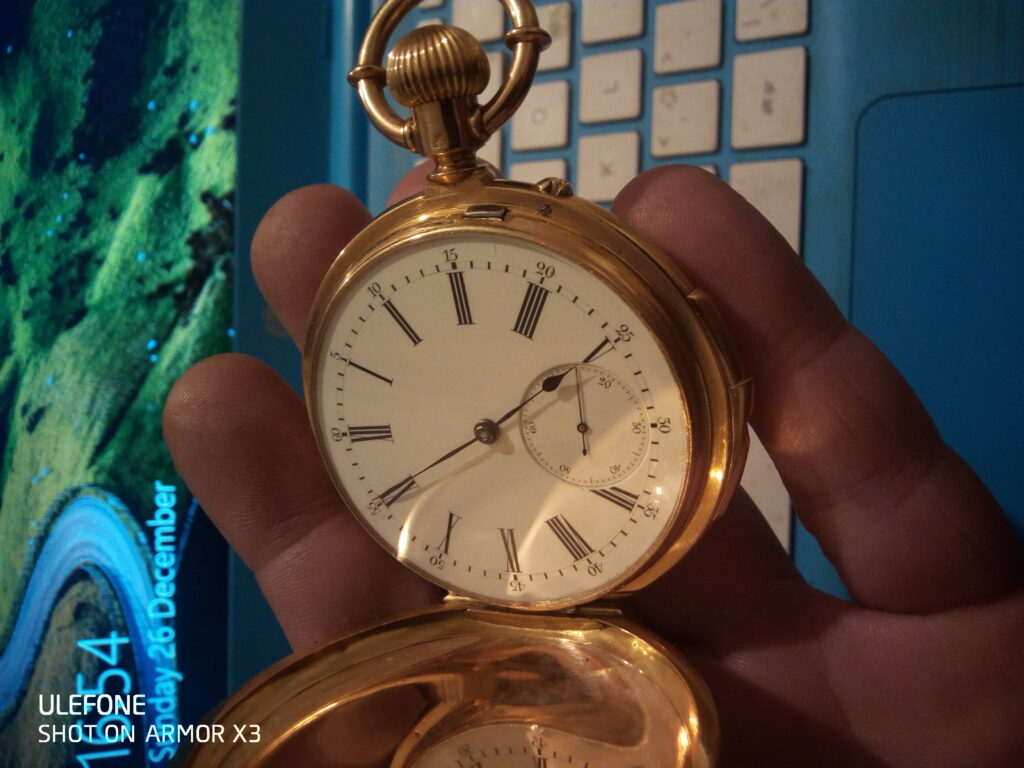

Hand forged / fired Glass Pocket Watch Glass job

The subject line says it all really, in that we had an expensive pocket watch in with broken glass. The glass was particularly thin and nothing “off the shelf” was ever going to fit. So we made our own.

We did this by cutting the glass blank with a ceramic lathe to exact diameter and then, having made a jigg, used a glass furnace to recreate the original convex curve. The end job is indistinguishable from the original although it is stronger, perfectly polished and a peffect fit.

The cost for this, including a very thorough service was under £1000 on a chiming gold pocket watch valued at around £7000. We are brilliant value for money and have equipment which others simply dont have. I genuinely believe that this job would have had to go to Switzerland for serveral times the cost and I doubt the job we made of it was not just incredibly cheap but also the best possible results in terms of quality finish, materials and strength.

I dont usually do bragging articles but the reason I am doing so on this occassion is that if you a have smashed special fit glass we can do it and we are one of very few organisations that do.

Brilliant job of which we are very proud.

Fusee Clocks – what and why

Ok I did an opinion article and I owe the blog a good tech article for the clock enthusiast.

Spring driven clocks are not accurate without a fusee movement. Thats a massive controvercial statement in clock terms. It means that your grannys 1960 mantle clock probably tells the times accurately twice a day. You dont notice because you get the time from your phone or your watch or the TV. But its true.

To qualify this I am making this statement only in the context of pendulum clocks with a short (say 6 inch max) pendulum. The almost direct opposite applies to long case clocks with long pendulums.

A pendlum clock can be simplified into three elements. 1. Power 2. Gearing 3. Regulation. This is the device that divides up time. It could be a pendulum or a balance wheel or a verge escapement or and atomic decay cycle etc. Notice that I have not included any category for hands and face because I clock does not have to show you its working to be accurate. Displays vary. Mostly they are dials but then you get barometric devices that output a line to a graph paper on a drum that rotates on a weekly basis. Its still a clock in essence.

Now, given that you have these three element the most important thing is that everything continues to whizz and whirr at EXACTLY the same rate. This is achieved with item 3, Regulation. Regulation in a pendulum clock is pereformed by…the pendulum.

A pendulum with a fixed centre of gravity will continue to swing at the same rate if no friction is applied. The friction is the bend in the spring at the top of the pendulum, the light touch on the crutch fork on each swing and air resistance. A pendulum of about 1 metre will swing at 1 second per swing. It will only slow down because of the friction wind/string/crutch friction. Forget the crutch thing – just consider wind and the bendyness of your pendulum as the things which cause friction.

Ok so you swing the pendulum with pallets. Describing this is going to be a challenge. So…

The spring is the power plant that turns/pushes the cogs leading up to the top of the clock. Its essentailly a mini engine connected to a gearbox of gears. By the time the spin has been passed from cog to cog – usually about 3 “wheels” (cogs) the last cog is spinning freely at hundreds of revolutions per minute vs the very slow crawl of the power plant at the start of the gearing down process.

So what you end up with is a turning wheel at the end of all that. The wheel is cut so that it looks rather like a cog but is nothing of the sort. Its rather like a cog but each tooth is a sharks fin. Theres a reason for that.

You see that top sharks tooth wheel is the thing that makes the pendulum swing. It does it by getting each tooth, in turn, to push a pallet. A pallet is a bit of flat metal connected pretty directly to the pendulum. So as the sharks teeth pass the pallet it nudges the pendulum one way and by the time the pendulum swings back it blocks the path of the pallet again and the process repeats.

Even if you didnt really understand that what may have occured to you is that the push from the sharks tooth has to be hard enough to counter the friction from from the air and spring friction.

If the sharks tooth is pushing hard enough the clock keeps going becuase the pendulum keeps swining, and if its stops then it means the pendulum is not being pushed hard enough by the pallets due to dirty gearing and no oil.

That was so hard to explain in a few paragraphs. If you didnt understand it then you may be suffering from “brain cavities”. I think I may have brain cavities because Ive just read it back and, bearing in mind I wrote it, I can barely understand it. Right. Whats a fussee.

I said your grannys clock isnt accurate. Then I explained how a clock works. The reason I did this is that if you get the first bit about a clock being a simple device to measure how many times a pendulum swings a minute, then the fusee is an easy extension of this.

The whole point of having a spring and a gearbox in a clock is to push just enough energy into the swing of a pendulum to counter the friction forces. Its a tiny amount of power to add to the each swing. Imagine swinging a your friend on a playground swing and keeping them going at the same rate by breathing in their direction. If you wanted to keep your friend swinging you just covid cough in her direction and off they would swing. Interestingly they would swing a bit further if you coughed hard and less so if you just coughed normally.

Now, a spring fully wound will cough harder than one at the end of its infection. This means that Newtons laws of physics are violated by the input of extra power to the system thereby creating an artificial, and therefore intrinsically innacurate method of regulation should the extra power going into the system reduce. Which it does.

The reason I just scientifically upped the stakes with my last sentence was that your so far through this that Im betting you will carry on….maybe. I will never know to be honest as Im too busy to check the website statistics which all appear to be in Greek – Its all Greek to me.

So the fusee is an ice cream cone shaped cotton reel, or larger. that acts as a variable ration gearbox in the cog sequence in which it is second. The first is the spring. The spring drum and the fusee ice cream cone are connected via a chain or wire which wraps around one or the other. If its wrapped round the spring drum the clock is unwound. If its wrapped in ever increasing diameter loops round the ice cream cone then the clock is fully wound.

[When the clock is fully wond it has a stop system inside that wil not allow you to move the key further. Its solid and distinctly different from the normal wind pressure. The reason its there is so that you dont give it the beans and snap the fusee wire – these clocks have and easy but long wind to accomodate the “gearing”.]

Fusee movement were invented……ages ago. I have to idea but Ive seen them on clocks to 1700 and I think 1690 (im not sure it – was an expensive bracket clock) so quite early on. I think the reason it did not become a standard feature were multiple

- Difficult to engineer the ice cream cone drum on which to wind the wire from the spring drum. This is not at easy bit to make. Firstly you have the problem that it cant be lathed without a lathe capable of operating from a copy or being programmed. Imagine having to make a perfectly accurate helter skelter from brass. In 1680. Evidence of Aliens as far as Im concerned.

- Maintenance. This system is more complicated. It has less set pieces you could stamp out of a sheet or cut with a jig. The implications of the string snapping on a full wind (which is obviously the point at which its most likely to snap) are slightly horrific. All the energy from a 55mm x .5. x 100mm spring releases into the clock putting immense recoil pressure on the first wheel. This means the gearing on the ice cream cone goes flat. You loose a tooth or two. This is SPECTACTULARLY expensive to get repaired. I wont do one. Affordably.

- Its all very well having these brilliant methods of transferring torque and mixing things up a bit to get what you need. It is. You see the majority of fusee clocks we see are not 17th century guilt portable chronometers (pffft – accurate to a minute a day if its working), they were school and station and company clocks. Utilitarian devices. They were designed simply, and oddly, to a build profile common to all manufacturers, and they HAD to show the right time clearly, hence the tendency for mid sized (12″ white face) to large clocks . You cant miss your train because the clock is worng. You cant be late for work and argue your clock is more accurate than your employers. These clocks, these municipal and railway and council office clocks are BRILLAINT. They say so much more about the leap of our society where you didnt turn up and 8.47am and leave at 5.25. You worked 9 to 5. Hard. The other delightful thing about them is that wood they used was not veneered. You get solid plank with varnish and polished. The simplicity of the external design and the high specification of hard wearing woods is fit for purpose, but of course we know the longer terms benefits now. Most have knock mark which shows its not from Marks and Spencer and there is even a key on some (“I wasnt late – look at the clock”). The star is of course the movement. The plate, pallets, arbours, bushes, the whole lot could have come out of a Messerschmidt 109e (plane, ww2, sorry. It was awesome) for the build quality. They cost a sunken galleons treasure chest to restore mechanically but your cant repair good quality with bad quality. Well you can actually. Punch bush, flatten and reposition the escapment, polish the arbours. To do it properly you need a spring change and that bit is not fun. Its 55m of .5mm carbod steel held with alloy bendy wire that has to go into an aperture with 2mm tollerances, usually with some sweaty mods to the coil size with a spring winder. If it uncoils half way through Im Ok. Thats because I wear a full really expensive full leather apron, gloves fit for Apollo and one down from a welding mask.

FOR SOME REASON, PROBABLY TO SAVE YOUR ENGINEERING “I CAN DO IT” MENTAL ILLNESS, DO NOT CHANGE A SPRING. ITS HONESTLY REALLY HAZARDOUS. THE PROBLEM IS THAT IF YOU LOSE CONTROL OF THE SPRING, IN THE PROCESS, THE EDGES, BEING CURVED, TAKE AN UNPREDICTABLE PATH AS IT UNFURLS.

THIS HAPPENS IN A SECOND AND CAN HONESTLY MAIM / BLIND / REMOVE FINGERS. EVEN IF YOUR CONFIDENT DO NOT UNERESTIMATE THE FEROCITY ON AN UN-CONTROLLED SPRING RELEASE. ITS A FLYING KNIFE SNAKE.

Our Brilliant NHS Workers

We live in a country where healthcare is free to all. As we are all aware people who work in the NHS are all part of a big team put together to keep us alive and without the need to worry about huge medical bills as well as your illness.

Thats absolutely brilliant but the people who enable this system are underpaid for the risk they take to save your life.

We are due another stretch of covid variant and the nurses and hospital porters and surgeons are going to risk their lives to save somebody you know. How can you thank people for something like that. Also this time last year we were all outside clapping the NHS staff whereas now we seem to be taking it all for granted and see it as our own problem with the NHS less considered.

I cant cure a covid sufferer or even guess how to help with the medical side of things. What I CAN do is make the lives of those who put theirs on the line is offer my services at a 50% reduced rate.

So thats the new policy.

If you work for the NHS then you get a 50% discount on all labour charges up to £500 (I cant extend this to parts cost unfortunately).

Thank you to all NHS workers. What you do is really appreciated and courageous. I dont care if you work in the back office or do the laundry or your a surgeon – your all fine people and Ill happily work at a discounted rate for you because we know you love your clocks and we love you!.

There are some limits on how far I can go with this as I have to pay the bills too but Ill make your clock bills good deal easier to pay. If you could mention your NHS employed and send a pic of your NHS ID tag in your initial email then Ill make sure you pay a good deal less than…people who dont work for the NHS!. The other thing I can do for NHS employees is staged payments. Ill work on a 3 month staged payment plan if this makes your life easier. Thats what Im doing. Not exactly saving a bus load of nuns and kittens, but something at least.

You probably dont work for the NHS and are reading this purely because you read my blog. Have you thought about what you could do for NHS workers?. Its not something that immediately springs to mind when all we hear is bad news but Im sure there is something you can do for NHS workers somehow. I dont know what that might be or how you might implement it, however, these people do and will need our support. A donation to the NHS is laudible but does it get through to the people who do the work and take the risks?. Call me cynical, but I doubt it. If you can do something directly for an NHS employee I would say that its the way to go. that assumes you want to help and you can. If you dont and you cant then fair enough. Im not trying to change the world or judge anyone. I mean fine. You sit there with scantily clad maidens feeding your peeled grapes and then call an ambulance because you need your fingernails cut. Medically. And your not paying. I mean do you have to pay for everything. What are the overheads? Clippers I suppose. No, theres not judgement going on here.

Joking aside, if you know an NHS worker why not offer an open invitation to dinner once or twice a week so they don’t have to cook when they get home. It sounds odd and overly personal but thats how I grew up. There was more community. And how much time does a nurse or hospital porter get to mow the lawn or wash the car. I know it all sounds rather high minded and vaguely religious but when I grew up in the 70’s people were like this already. You knew your neighbours as friends. Things were just more socially integrated despite the absence of Facebook/Meta and computers. People did spend a long time on the phone mind you.

My point overall in offering an NHS discount is more about that sort of thing. Its got nothing to do with money from my point of view. Theres no publicity, no headline, just what I hope will become normality. Quite frankly it went wrong with the digital watch in my opinion. I was getting my first Timex Junior when the rich kids had red LED watches that lit up and told you the time in writing!. As an aside, Ive had three since, each of which has failed almost immediately and seems unrepairable but I still love them. Anyway, given that there is a chance of the NHS getting overwhelmed I believe its probably time to think about offering support, in whatever way, to those on the front lines.

I rarely do this type of article because who cares what I think. People want to know what I know about clocks and hear about interesting clock related things, however, there is a tenuous link in that Ive had a few NHS customers recently and the only reason they got their (prior) 25% discount was that I tend to get to know my customers to some degree and they obviously mention or refer to their work.

I cant become “Dr Clock” and just do NHS work so Ill have to limit it to a couple of clocks per month but that allowance should be more than adequate. If it goes over this estimate then Ill either cut the service and offer it to certain people on a face to face basis, or ill cut back the percentage or limit the financial elements in some way. Just a warning!.

Ill do a clock article now.

Recent Comments