Alan Turing Vs Early American Clocksmiths. (Clocks win).

Read this is your looking to repair an electric pendulum clock from the 80’s as it could save you a lot of frustration on ordering cock ups if you want to have a go yourself. But dont do that – get me to do it ;-).

Rather than reproduce the hints Ive just pasted an email I sent to a recent enquiry – its got all the info and you can see how I approach my jobs / customers at the same time!.

“Its likely to be a high tork electric pendulum movement. I did one today – a Seiko. Its a walk in the park to fit it providing you confident with getting the hands off the front. These might just pull off or there might be a screw or lynch pin holding them on. Remove the hands and replace the movement with an identical one and you are done. Finding an identical one is either easy or mindbendingly boring. Essentailly there are probably 5 movement types available globally on ebay. If you have one of those then its and easy job. If not you have to buy a donor clock – basicly find your clock or one using the same movement and then use that.

The things its easy to mess up if you are taking the DIY approach.

1. Spindle length. This is how far the nose of the movement stick out. If its not enough it wont clear the clock face and if its too much the nose hits the clock glass and stops the hands.

2. Hand appeture width. You have to vernier guage your hands inner holes and then order the right option with the movement. Its that or alternatively use the hands that come with the new movement. This isnt as bad as it sounds – most movements can be bought with a reasonable choice of hands. This link is the sort of thing you are after but I can advise on the exact item once you have sent a photo.

If you dont want to go through what is mostly specification and ordering hassle then get me to do it. Cheers, Justin”

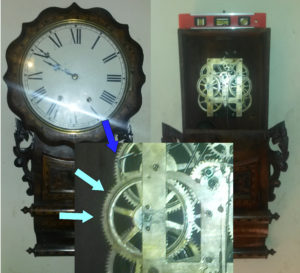

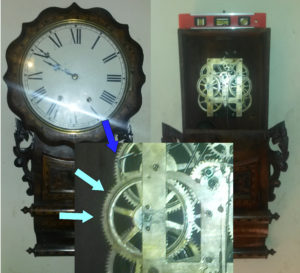

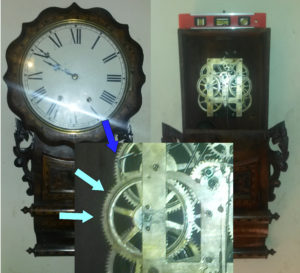

When you send a wall or long case clock, or even a mantle clock there are a few rules to obey if you want the thing to turn up working when it is upacked. The most important thing is to unwind the clock. To to see how to do this follow this link. If you dont unwind the clock and the clock loosens up in transit from vibration or knocks then the lynch pins holding the plates together can fall out. The end result of this is probably easier to explain with a mataphor. Imagine you had a safety pin connecting the two sides of yoru rib cage togther. Releasiing it will result in the ejection of your inards. This, in the case of the clock, happens rather violently and often causes serious damage to the coggs themselves see below where the bar courousel has lost some of its spiggots.

I redrilled the holes in inserted new rods by the way – the clock is back to its excellent functioning self. The blue ring highlights the corousel and its stantion bars taken out for replacement. You cannot do this without a high precision thick drill and I was using a cobalt .3mm bit. If you mess up the positioning of the bars the whole clock will cease to function so do be careful if you are attempting this yourself.

The other really important thing to do when transporting a clock is to remove the pendulum. Even if you cant see its fixing you can still lift it which should be enough to un-mount it from its hanging point. If you dont do this then two things will happen during transport.

If you have a clock you would like repaired thats come to you as a box of bits just give me a ring!.

Clock on people.

Justin

Oh – heres the clock it came out of. An absolute corker. American turn of the century with a movement that moved me!. Really nice one.

When you need a new mainspring in a movement its normally possible to source a unit from a range of sizes and variations. There are a number of online retailers who supply enthusiasts and trade customers like me.

Every now and again you come accross a spring that cant be sourced. In these cases I have to manufacture the spring from spring strip. This is quite a process and I thought I would share it with you.

Before I continue I feel compelled to say that this is not something you should attempt yourself. Its dangerous when a spring uncoils uncontrolled and you are essentailly dealing with a high speed out of control carbon blade. So dont do it.

My method is very old school because I enjoy setting myself the challenges of the original craftsmen. It produces a much more authenic product and means that I really get to know my components very well. This allows me to predict and tailor how they will perform when installed. And its great fun high kudos clockery of course.

Heres a quick picture journal of one I did today.

This is the basic raw material. In this instance is 145cm length, 2cm height, and .5mm thickness suitable for a 45mm barrel diameter. Theres a calculation you have to do I wont bore you with.

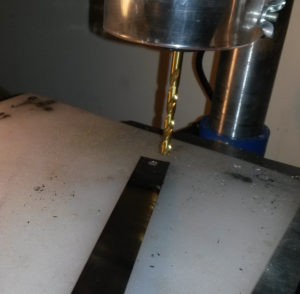

The next shot shows the end holes being drilled. The spring wire is so carbon toughened that you cant drill it without first heating the area to be drilled red hot. This reduces the stresses in the metal, burns the carbon out, and makes it closer to mild steel the more you heat and slowly cool. Drilling still requires a cobalt bit in my experience, or HSS if your on a budget. I normally use cobalt because they are stiffer and hold their position well. HSS tend to skate a bit on hard surfaces and are unusable on a hand drill. My drill is a bench mounted unit which is an excellent investment as a general tool anyway. The bit bellow is HSS simply because cobalts of that guage are quite pricey. HSS is better for larger bits!.

Compressing the spring requires a modern spring winder (boring) or a wooden jig with a central metal core for the winding. The jig needs to be braced with wire before any pressure is applied. Once its tight all round then the spring is wound. The picture above shows the wound spring ready for fixing with a wire retainer.

The end result is the bound and coiled spring ready for insertion into the barrel.

Once the spring is pressed into the barrel its ready to fit the arbor.

I always cut a deeper fastening point on the arbor for good measure and to ensure it catches the spring firmly if the clock is ever reverse wound (which disengages the arbor so dont do it).

Thats a quick overview of how its done on a bepoke. If its a stock spring you can see which bits I dont have to do although the majority of the work on a spring change is getting the entire movment disassembled as the spring is really deep in the heart of the mechanics.

If you think you have a broken mainspring and would like me to replace please give me a call. You can tell your mainspring is broken by turning the key – if it meets some resistance and winds a bit bofore “slipping” you know you have a break in the middle of your mainspring. If the key turns with no resistance than that is better news as it means the spring may have slipped its arbor and can just be reconnected as opposed to replaced which is about half the cost.

Main spring replacement is something you should consider as part of a regular e.g. 10y yearly, service on a mechanical clock. Over time even the best springs will lose thier power as they are wound and released. If you are thinking of getting your clock serviced because it keeps stopping unexpectedly then think about getting the main spring done at the same time. Yes it does double the cost from about £60 to over £100 but the spring itself accounts for the majority of this higher service cost. Overall, if you plan to own the clock for your lifetime its the best way to go about things and actually cheaper than cleaning and spring replacment as two different services delivered on two jobs.

The pics here show a relatively modern 14″ bracket clock. Its a beauty for a modern clock and really has gravitas in much the same way as a grandfather clock does. Its become another clock on my wish list but that is already impossibly long as I tend to bond a bit with all the clocks I work with.

The pics show the movement re-assembled ready for its new spring and top plate refitting. Note the excellent condition of the movement overall – the point here is that it can look as clean as the day it was sold but over time the spring will wear down. This clock was running consistently for 4 days on an 8 day spring and fading over time. If you have the same problem you know who to call!.

I recently repaired this Mora clock. These are quite rare now and originated from 18th century to the middle of the 19th. They are really good looking clocks and thier shape in sweden is as iconic as the grandfather clock you or I would envisage.

I recently repaired this Mora clock. These are quite rare now and originated from 18th century to the middle of the 19th. They are really good looking clocks and thier shape in sweden is as iconic as the grandfather clock you or I would envisage.

This particular clock is old and I am advising the owners to reasearch it a bit as it is marked A A Anderson on the front who was the very first Mora clock maker operating from Ostnor in the middle and end of the 18th century.

To find out more about Mora clocks visit this link to its Wikipedia entry which covers all the basics.

The main reason for this post is really just to show a rare clock however a few lessons were learned by the owner as part of the repair. The most important of these is that whenever you ship a pendulum clock it is essentail to remove the pendulum. If you dont do this then the pedulum will jump around and either bend, break or crease the leaf spring on which it is suspended. Hope you like the clock and for more about Mora clocks.

I was asked to do this by a client. Its not that difficult to do but you will need:

How to do it

If you cant be bothered with all this you can buy a new one for about £125, but as you can see from the price its time well spent refurbishing the clock. Also you get an accurate modern clock in the van.

For a very long time now I have waited for a call to come in asking for assistance in repairing a clock that has suffered party damage in the abscence of parental law. Today it happened. These two are responsible for it. I cannot name them – on these types of black operations we dont use names.

The official story is that they were sipping at a half of shandy while discussing the merits of charity work when they noticed a kitten trapped behind the clock. There was no time to waste as the cat could also have been hungry as well as trapped. Obviously the clock needed hacking into with a fire axe and then a good kicking.

I

I

In normal circumstances it would be fair to predict a really really good hard bollocking accompanied by various agressive sanctions on personal freedom and finances. That is unless you can get some idiot to come out on bank holiday Sunday, not charge you a fortune and enter into the conspiracy with you. It would also be a bonus if the same person could get the clock running and actually leave the clock better working order than before it was abused by the reckless actions of a kitten.

All part of the service and a landmark day for me. Thanks guys.

Pocket watches are great fun to work on. Its the mechanics that constantly amaze me on older watches. They will stop if you dont get them serviced every few years because they are very very sensitive to the accumulation of dirt. How does the dirt get in there? you might ask. The only way it gets in there is from particulates in the air that you cant see. The watch could condense these out of the surrounding air if it is cold and brought into a hot environment. The other big one of course is smoking. If you smoke your gunging up your clocks much much faster than normal – I know becuase most of the cleaning I do for restoration is infact nicotine and dead skin – mmmm lovely (I still love the job).

Pocket watches are great fun to work on. Its the mechanics that constantly amaze me on older watches. They will stop if you dont get them serviced every few years because they are very very sensitive to the accumulation of dirt. How does the dirt get in there? you might ask. The only way it gets in there is from particulates in the air that you cant see. The watch could condense these out of the surrounding air if it is cold and brought into a hot environment. The other big one of course is smoking. If you smoke your gunging up your clocks much much faster than normal – I know becuase most of the cleaning I do for restoration is infact nicotine and dead skin – mmmm lovely (I still love the job).

Anyway this is a pocket watch a did recently. You can SEE all the components and how they communicate forces between each other. If I get a TAG Hauer or a Burberry in (two recent jobs) its just a matter of replacing the whole movement becuase they are mass produced and the same movment will be used by completely differen manufactures. Frankly its boring work to do as a clock repairer and I far prefer pocket watches.

This picture shows an old British Rail station masters watch innards. From the top down you have the drive wheel and additonal cog that keeps the movment going as you are winding it up (clever). The brass cogs then gear down the power and deliver it to the escapement wheel you can see at the bottom under the last brass cog. This escapament cog is always under tension from the spring and is alowed to advance one tooth at a time by the back and forth movement of the flywheel. This regulation between the flywheel and the escapement wheel is managed buy the pallet fork which you can just see sticking out from under the escapement wheel. This is a see-saw affair eith the wheel at one end and the pallet fork at the other end. You can see the other end of the fork in the picutre as they are red jewelled rather conveniently. The picture doesnt show the flywheel which I have removed to show the whole drive chain of cogs.

So if youve wondered what all the gubbins inside the pocket watch actually does, now you know. Its not a complicated machine but that means it has to be very finely engineered as well, hence its sensitivity to dirt build up from the air.

Hope this enlightens you.

I have been asked to repair this grandfather clock, specifically the pendulum spring which requires replacing and riveting.

As a bit of practice I had a shot at accurately dating this clock from its features.

I had a good look at the dail composition, the engraving quality, the half hour markers on the chapter ring without quarter markings and the basic construction of the brass back plate (which uncommonly, is two connected plates).

The quality of the chapter ring was surprisingly good – it looked machined or turned at least although there is one small casting fault on the edge of the ring at III. The engraving looks hand performed with some tooling marks apparent under close inspection. The centre of the dial features some basic engraving around the date ring but is not of the same quality as that on the dial. The rest of the engraving on the plate e.g. tram lines on the perimeter, is also simply produced by hand. This contrasts with the spandrel which are are well cast, quite detailed and good quality with a marine theme. They are also original to the clock as there are no signs of redundant holes in the back plate. It is, as far as the “clock” is concerned, a nicely original item. Having considered all this it suggested the clock was 1730 as this is when these various features would have been concurrently evident on the dial.

I was therefore somewhat grattified when research revealed that John Bruce started his apprenticeship with John Perkin in 1723. It is known that Perkin was making clocks in York in his own right by about 1730. This ties in with the owners belief that it was a norther clock although the case was surpisingly reserved compared to later northern clocks I have come accross. Apologies for not including a picture of the case – I will add this later when I return the repaired pendulum.

Interestingly I found a picture of a John Pirkin clock which shows what he was capable of and would have driven John Bruce to aspire to ((pic on Brian Loomes’ site)). The Bruce clock I am working on is less sophisticated mechanically and decoratively compared to the Pirkin clock so I expect the clock I am working on was an early one for him. There are of course people who know more about these things than I do so any comments on this post would be most welcome – as a clockist I am information hungry!. If Im wrong I prefer to know and never take it personally.

If you are reading this and have a grandfather clock to date please do feel free to email a picture and I will publish it here with an explanation of the date I believe it was made.

Below: The Perkin Clock – click the pic to visit the site source, Brian Loomes excellent site and source of information. He also writes excellent books packed with information in an interesting narrative format.

Recent Comments